we consistently create with pioneering dedication

craftsmanship and advanced technology

Horgenglarus combines highly specialised craftsmanship with state-of-the-art CNC-controlled precision technology. This symbiosis allows us to produce small series to the same quality of one-off products. The result: tables and chairs considered everyday furniture, beloved furnishings, valuables and cult objects.

Precision and care

Working with wood requires an acute awareness of the material and its properties. For almost 150 years, we have been crafting this raw material into the highest quality furniture.

During this harmonious interplay of traditional craftsmanship and state-of-the-art technology, a chair goes through around 50 precise work steps, each of which is part of a process that demands the utmost care and precision – an investment in quality that lasts for generations.

Our strive for perfection is reflected in every piece. Every detail is a commitment to the highest standards.

Wood

As a living, renewable raw material, wood is characterised by its natural beauty and excellent processing properties. It has always been the ideal material for environmentally conscious and resource-saving furniture production. Horgenglarus chairs and tables are mainly made of native wood from the Swiss Jura, which we have been purchasing from Groupe Corbat since the 1920s. This long partnership with the family business gives us the privilege of getting first access to the best tree trunks.

We process beech, oak, maple, elm, cherry, walnut and ash as solid wood, peeled or sliced veneer, with various surface finishes: clear or opaque lacquered, stained or oiled.

Colour Card 2025

Cutting

First, the sawn timber is cut and planned, in several passes, down to the right size for the backrests, armrests, back and front feet or sides. Any waste timber is then incinerated directly in the heating system, which supplies energy for the drying chambers.

Bending

Wood bending is the heart of our manufacturing process. Here, the cut workpieces are treated with hot steam, which softens the cell structure of the wood and allows the workpiece to be bent into the desired shape in the bending machine.

In the drying chamber, heat is used to remove any moisture from the shaped workpiece, which is clamped in a mould over several days. It then retains its new shape without returning to its original state and is ready for further processing.

Since the annual rings are not cut out during the bending process, the robustness of the wood is fully preserved, lending our chairs unrivalled stability.

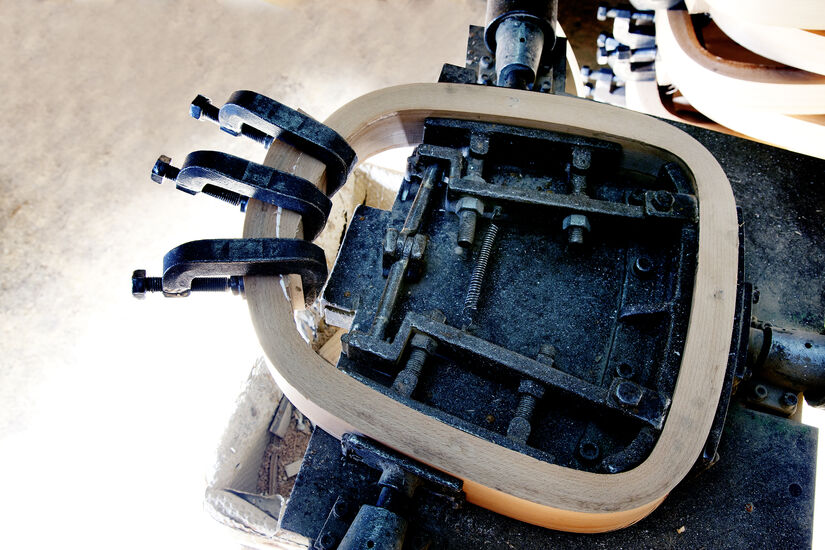

Round frame

The solid round frame is a characteristic feature of many of our chair models. After the drying chamber, the cooled curved frames pass through around 25 further processing steps. First, the joint where the frame is then glued together is cut out. The frame is then passed back and forth between a specialist craftsman and a precisely programmed CNC milling machine several times until it is finished.

Milling

Today, many of the work steps at Horgenglarus are carried out by state-of-the-art computer-controlled milling machines. The cutting edge of the rotating milling tool is moved along the coordinates specified by a digital design until, chip by chip, the intended shape of the workpiece is realised. The CNC milling machine enables high-precision, repeatable and automated production of complex furniture components.

Sanding

Once in their final shape, the workpieces are professionally sanded by hand several times in the sanding room until they feel silky-smooth and soft. Care is taken to work in the direction of the grain so that there are no scratches or grooves. All visible and invisible edges (e.g. on drill holes) are sanded down to prevent the splintering of wood fibres and to ensure an even distribution of stains, lacquer and varnishes.

Assembly

The individual sanded parts of a chair or table are then screwed or glued together and precisely assembled to form a piece of furniture.

Surface

The individual sanded parts of a chair or table are then screwed or glued together and precisely assembled to form a piece of furniture.